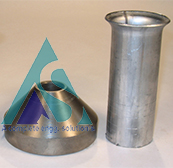

Inconel 601. Alloy 601, UNS N06601, High Temp. Alloy 601 Ferrule (Tube Insert).

Aditya Steel Engg. Co. is a high slit enthusiastic manufacturers and suppliers of High Performance Alloy 601, UNS N06601 Ferrule (Tube Insert) for reformed gas boilers and heat exchangers.

Alloy 601 Ferrule (Tube Insert).

The material for Ferrules (Tube Insert Sleeves), Inconel Alloy 601, UNS N06601 is a high nickel-chromium alloy used in applications requiring resistance to heat and corrosion. Due to its exceptional resistance to high temperature oxidation, which lasts beyond 2200° F, this nickel alloy stands out. Even under extreme temperature cycling, Alloy 601 generates a strongly adhering oxide scale that resists spalling. This nickel alloy maintains its ductility even after extended service exposure and has exceptional high temperature strength. It is easily produced, machined, seamless, and welded, has a high mechanical strength, and has strong resistance to water corrosion.

Aditya Steel Engg. Co. is high slit enthusiastic about producing high-quality Alloy 601, UNS N06601 Ferrules (Tube Inserts) for increasing boiler and heat exchanger life and corrosion resistance. Since over 20 years, we have comprehended our clients’ needs and applications and have been a trustworthy partner in the production of Alloy 601, UNS N06601 Ferrule (Tube Insert) for the reformed gas boilers and heat exchangers. We go where our consumers go – We use high quality reputed mills raw material of Inconel Alloy 601 for ferrules (Tube inserts) from USA, Europe, Japan.

Forms of Inconel 601 available with us.

Seamless Tube Ferrule.

Welded Tube Ferrules.

Seamless Tube Insert.

Welded Tube Insert.

Seamless Tube inlet Ferrules

Welded Tube Inlet Ferrules

Seamless Tube inlet sleeves

Welded Tube Inlet Ferrules sleeves

Plate

Round Bar

Buttweld and forged fittings

What are the Advantages of Inconel 601?

- Outstanding oxidation resistance to 2200° F

- Resists spalling even under severe thermal cycling conditions

- Highly resistant to carburization

- Good creep rupture strength

- Metallurgical stability

Alloy 601 Chemical Properties

| Ni | Cr | Al | C | Mn | Si | Fe |

|---|---|---|---|---|---|---|

| 61.5 | 22.5 | 1.4 | .05 | .3 | .2 | 14 |

Mechanical Properties

Typical room temperature Properties

| Tensile (psi) | .2% Yield (psi) | Elongation (%) |

|---|---|---|

| 80,000 | 30,000 | 35 |

In what applications is Alloy 601 used?

- Chemical Processing

- Aerospace

- Heat treating industry

- Power generation

- Heat treating muffles and retorts

- Radiant tubes

- Catalyst support grids in nitric acid production

- Steam superheater tube supports

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet / Plate | Bar | Forging | Fitting | Wire |

|---|---|---|---|---|---|---|---|---|

| B167 | B517 | B167 | – | B168 | B166 | B564 | B366 | B166 |

Our All Product Facility

Api 5l Pipes & Tubes., ASTM A335 Alloy Pipes, Stainless Steel Pipes & Tubes., Stainless / Carbon Steel Plates and Sheets., Chrome Moly A213 Boiler Tubes, ASTM A213 T5 Chrome Moly Tubes, ASTM A213 T9 Chrome Moly Tubes, ASTM A213 T11 Chrome Moly Tubes, ASTM A213 T22 Chrome Moly Tubes, ASME SA387 Chrome Moly Steel Plate, Swaging Boiler Tube – Swaged Tube, Pipe Fittings., Stainless Steel Fittings, B16.9 Butt welded Fittings, ASME/ANSI B16.9 – Fittings, B16.9 Butt Welded Unequal tee, B16.9 Barred Tee / Bar Tee, Butt Welded Con. and Ecc. Reducer, Butt Welded Straight (Equal) Tee, Butt Welded End Cap, ASTM A234 Chrom-Moly Reducer, ASTM A234 Chrom-Moly Tee, B16.5 – Pipe Flanges & Flanged Fittings, EN 1092-1 Flanges , B16.9 High Nickel Alloy Fittings, B16.9 Hastelloy C276 Fittings, B16.9 Inconel 625 Fittings, Ferrule – Tube Inserts, Alloy 602CA – Ferrule (Tube Insert), Alloy 601 Ferrule (Tube Insert), High Temp. Tube Insert Sleeve, Metal Tube Inserts (Ferrules), Virgin PTFE Tube Inlet Ferrule, Sleeve ,Pipe Sleeving, Internally Insert Pipe Sleeve, Internally Pipe protaction Sleeve, Pipe Insert Sleeve, Repair Pipe Half Sleeve, Industrial Valve’s, Flanges, Gaskets & Flange Insulation Kit, Monolithic insulation joint – MIJ, Fasteners, Steel Equivalent, Pipeline Leak Repair Clamps.

OUR MAIN MANUFACTURING, FABRICATION AND EXPORT COUNTRIES:

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles