Manufacturers and Exporters of Internal pipe sleeving, insert sleeve, pipe insert sleeve, pipe weld sleeve, weld sleeves and internal protactive insert sleeve in Mumbai, india

A Corrosion-resistant sleeve that keeps liquids out of the joint zone while withstanding welding heat.

The way internally lined pipelines are constructed is changing thanks to our welded joint Sleeve technology. Finally, a system that employs conventional building techniques and offers long-term defense against internal corrosion and erosion. What matters most is what’s inside.

Pipe Sleeve For Pipe Insert

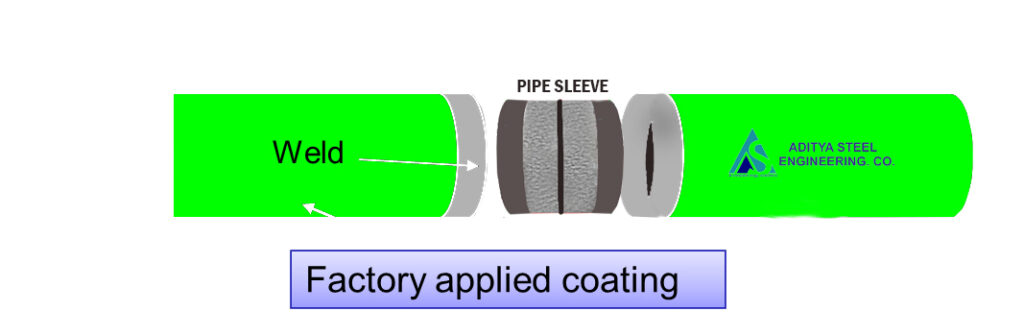

Pipe Sleeve is a welded barrier connection technique used to interconnect internally coated line pipe and piping systems. The pipe sleeve connection system makes use of an insert sleeve that is designed as a weld barrier method. Pipe sleeve insert fittings offer the same protection and may be made in any form, making them a cost-effective and versatile option for field construction, tie-ins, terminations, alterations, and repair of internally coated lines. These materials are compatible with all ASEC FBE coatings and can be used onshore or offshore.

ASEC’s plant can produce pipe sleeves ranging in size from 4″ to 30″

We are One of the company producing carbon steel pipe insert sleeves with the highest rate of growth is Aditya Steel Engg. Co. We provide these covers in standard and customized forms at a competitive price, depending on the needs of our customers. Aditya Steel & Engg. Co. produces these pipe insert sleeves in a variety of sizes, shapes, and dimensions in accordance with worldwide standards. This raw substance comes from a reliable exporter.

Engineers at Aditya Steel have thoroughly investigated the issue of avoiding internal corrosion in pipelines with welded joints. They can assist you in learning more about the available lining and joint solution choices.

The ADI pipe insert sleeve is a pipe internal weld sleeve specifically created to make a continuous internal coating transmission at the joint welding section of piping to protect the welded joint region from corrosive process fluids. This product can be manufactured in a wide variety of sizes, grades, materials, or piping system configurations, and it can be used in the field jointing of both onshore and offshore pipeline installations. The sleeve is suitable for pipe coatings made of liquid or powder materials.

The ADI pipe insert sleeve’s design goal is to provide a consistent internal coating for internally coated pipelines while taking into account the maintenance and cleaning tasks that must be done on the pipeline after installation. This will prolong the service life of the pipeline.

With a proper coating applied suitable for working under the specific transport medium conditions of each project, high temperature isolation treatment for pipe welding, and high temperature and corrosive resisting sealing rings and mastic epoxy, the pipe insert sleeve provides a satisfying protection for the pipeline’s internal cutback area.

The pipe insert sleeve produced by Tyhoo fits internally coated pipelines with an outer diameter that usually varies from 2 inches to 48 inches. (60.3mm-1219mm). For pipes larger than 12 inches, Tyhoo’s interior field joint coating is advised.

The outer diameter of the pipe insert sleeve, which typically ranges from 2 inches to 48 inches, is designed to accommodate internally coated pipelines. (60.3mm-1219mm). It is suggested to use ASE interior field joint coating for pipes bigger than 12 inches.

Engineers from Aditya Steel Engineering Co. have thoroughly investigated the issue of avoiding internal corrosion in pipelines with welded joints. They can assist you in learning more about the available lining and joint solution choices.

ADI Pipe Sleeve Advantages

| Flexibility: Thin-gauge assembly conforms to the shape of the conduit for simple insertion and reliable seal performance. | Heat Resistance: A wider sleeve and thicker insulation lessen the effect of heat while maintaining welding speed. |

| Sealing: Bore seals can withstand any pipeline pressure and can handle pipe ID tolerances. | Large Diameters: Suitable for non-round tubing |

| Flexibility facilitates a better fit, a simpler root pass, and more reliable weld quality. | Internal lineup clamps and automated welding are compatible. |

Pipelines benefit from the optimal strength and ductility of carbon steel pipe with welded joints. However, almost any liquid or slurry transported via pipeline (with the exception of sweet oil and gas) will corrode steel. The ASE welded joint system allows for the use of carbon steel pipe with polymer lining materials that provide long-term steel protection. The premium lining materials listed below are used in conjunction with ASE Sleeves and Joint Lock Rings to prevent pipe interiors from corroding.

Manufacturer of metal Internal pipe sleeve, Manufacturer of insert sleeve, Manufacturer of pipe insert sleeve, Manufacturer of pipe weld sleeve, Manufacturer of weld sleeves, Manufacturer of internal protactive insert sleeve in Mumbai, india, Dubai, Middle east, Europe, Japan, USA, Korea, and China.

Aditya Steel material grades for making of pipe internal insert sleeves.

Aditay Steel Engineering Co. is a well-known manufacturer and supplier of pipe internal coated insert sleeves in the special imported European, Japanese, and Korean raw material pipe grades as API 5L Line PIPES PSL 1 & PSL 2, SOUR SERVICE NACE MR0175, and engineers for oil and gas field pipe line weld joint protection providers. Grades 46, 52, 60, 65, 70, and 80 The following ASTM standards are used for internal pipe sleeves: ASTM A53, ASTM A106, ASTM A333, ASTM A36, ASTM A516 CL 60, CL 65, CL 70, ASTM A671, ASTM A672 pipe internal insert sleeves, ASTM A691, ASTM A312 pipe internal insert sleeves, and ASTM A358 pipe internal insert sleeves in Vasai, Thane, Mumbai, India

Aditya Steel Pipe Insert Sleeves Material Grade

API 5L LINE PIPES PSL 1 & PSL 2, SOUR SERVICE NACE MR0175, Grade x46, x52, x60, x65, x70, x80 | ASTM A53 | ASTM A106 | ASTM A333 | ASTM A36 | ASTM A516 CL 60, CL 65, CL 70 | ASTM A671 | ASTM A672 | ASTM A691 | ASTM A312 | ASTM A358 etc.

Api 5l Pipes & Tubes., ASTM A335 Alloy Pipes, Stainless Steel Pipes & Tubes., Stainless / Carbon Steel Plates and Sheets., Chrome Moly A213 Boiler Tubes, ASTM A213 T5 Chrome Moly Tubes, ASTM A213 T9 Chrome Moly Tubes, ASTM A213 T11 Chrome Moly Tubes, ASTM A213 T22 Chrome Moly Tubes, ASME SA387 Chrome Moly Steel Plate, Swaging Boiler Tube – Swaged Tube, Pipe Fittings., Stainless Steel Fittings, B16.9 Butt welded Fittings, ASME/ANSI B16.9 – Fittings, B16.9 Butt Welded Unequal tee, B16.9 Barred Tee / Bar Tee, Butt Welded Con. and Ecc. Reducer, Butt Welded Straight (Equal) Tee, Butt Welded End Cap, ASTM A234 Chrom-Moly Reducer, ASTM A234 Chrom-Moly Tee, B16.5 – Pipe Flanges & Flanged Fittings, EN 1092-1 Flanges , B16.9 High Nickel Alloy Fittings, B16.9 Hastelloy C276 Fittings, B16.9 Inconel 625 Fittings, Ferrule – Tube Inserts, Alloy 602CA – Ferrule (Tube Insert), Alloy 601 Ferrule (Tube Insert), High Temp. Tube Insert Sleeve, Metal Tube Inserts (Ferrules), Virgin PTFE Tube Inlet Ferrule, Sleeve ,Pipe Sleeving, Internally Insert Pipe Sleeve, Internally Pipe protaction Sleeve, Pipe Insert Sleeve, Repair Pipe Half Sleeve, Industrial Valve’s, Flanges, Gaskets & Flange Insulation Kit, Monolithic insulation joint – MIJ, Fasteners, Steel Equivalent

OUR MAIN MANUFACTURE AND EXPORT COUNTRIES:

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles