With the good experiacne in the sector oil and gas, we Aditya Steel engineering co. is high slit enthusiastic about supply from stock of ASTM A213 T9 boiler tubes in Mumbai, India.

ASEC is a high slit enthusiastic about Manufacturers, stockist and suppliers of reputable Indian SA213 T9 Tube Manufacturers, stockist and exporters. Due to the reasonable man hours in India and good sources of high quality ASTM A213 T9 Seamless Tubes at best price accessible in Mumbai, India, we are able to offer SA213 T9 Seamless Tube, ASTM A213 Alloy Steel Seamless Tube, Alloy Steel ASTM A213 T9 Tubing & ASTM A213 T9 Tubes at lower prices in India, Maharashtra, Mumbai. we are among the countries that receive ASTM A213 T9 material from Aditya Steel. The sizes and thicknesses of alloy steel ASTM A213 T9 tubing that are typically provided to this standard are 0.015 to 0.500 in. [0.4 to 12.7 mm] in minimum and 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter, inclusive.

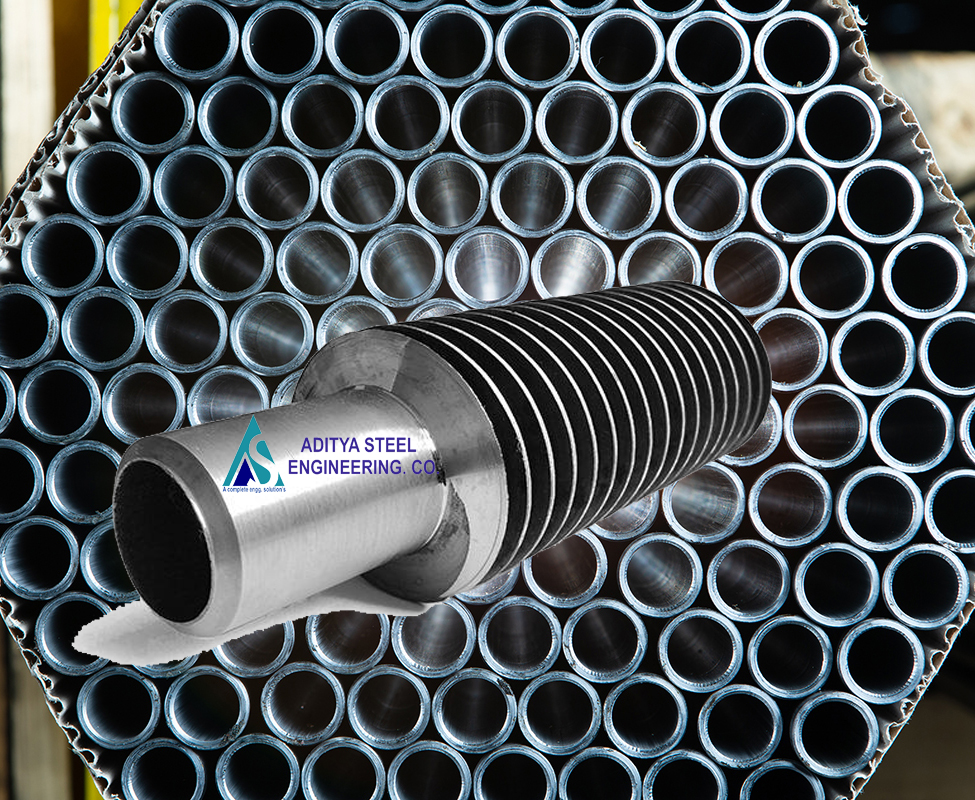

ASTM A213 T9 boiler tubes.

Aditya Steel Engg. Co. is high slit enthusiastic about stockist and supply high-quality ASTM A213 Grade T9 Tubes for durable heat exchanger and boiler heat. Since over 20 years, we have comprehended our clients’ needs and applications and have been a trustworthy partner in the production of ASTM A213 Grade T9 Tubes for the authorised market. We go where our consumers go – all around the world.

Aditya Steel engineering is an ISO CERTIFIED and Manufacturer and exporters of seamless/welded boiler tube, Stockist and suppliers of superheater tubes, deler and suppliers of high tempreture tube, stockist of astm a213 t9 tubes, supplier of astm a213 T9 tube, exporters of astm a213 t9 tubes, distributors of astm a213 T9 pipes, stockholders of astm a213 T9 tubes, manufacturer of astm a213 T9 tubes in Mumbai, India, Maharashtra.

Tubing with an inside diameter of less than 0.015 in. (0.4 mm) and a thickness of less than 1/8 in. (3.2 mm) is exempt from the mechanical property standards for ASME SA213 t9 chrome moly tube. Additional criteria are offered as options, and if they are necessary, they are noted in the order.

It is recommended to treat the values given in either inch-pound units or SI units individually as standards. Be aware that the specification may not be met if numbers from the two systems are combined. Unless the “M” designation of this specification is specified in the order, inch-pound units will be used.

| Trade Name | Grade | UNS # | Heater Tubes |

|---|---|---|---|

| 1 1/4 Chrome | T11 | K11597 | A213 |

| 2 1/4 Chrome | T22 | K21590 | A213 |

| 5 Chrome | T5 | K41545 | A213 |

| 9 Chrome | T9 | K90941 | A213 |

| T91 | T91 | K90901 | A213 |

| T92 | T92 | K92460 | A213 |

ASTM A213 T9 Boiler Tube Specification

| Additional Testing | NACE MR 0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, H2 SERVICE, IBR, etc. |

| Standard | ASTM A213, SA213 (with IBR Test Certificate) |

| Specifications | ASTM A213 & ASTM A209 (T1 , Ta, T1b) BS/3059/90/PartII/620 & 622 DIN/17175/13CrMo44 DIN/17175/10CrMo910 DIN/17175/15Mo3 |

| Tolerance | Cold drawn pipe: +/-0.1mmCold rolled pipe: +/-0.05mm |

| Length | Standard Double & In Cut length also. |

| Sch. & Swg. | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg., 3.6 mm Thk |

| Type | Seamless / ERW / Welded / Fabricated |

| Origin | European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| Size | 6.35 mm OD to 101.6 mm OD |

| Thickness | 3-12mm |

| Craft | Cold rolled and Cold drawn |

| available in Form of | Round, Square, Rectangular, Hydraulic Etc. |

| End | Plain End, Beveled End, Treaded |

| Specialized in | ASME SA213 Boiler Tube, SA213 Heater Tube, SA213 Heat Exchanger Tube |

| Tolerance | Cold drawn pipe: +/-0.1mmCold rolled pipe: +/-0.05mm |

| Application | Seamless Ferritic Alloy Steel Tube for High-Temperature Service |

ASTM A213/ ASME SA213 T9 Alloy Steel Tube uses

- ASTM A213/ ASME SA213 T11 for power generation, petroleum, and other high temperature services

- ASTM A213/ ASME SA213 T22 for power generation, petroleum, and other high temperature services

- ASTM A213/ ASME SA213 T5 for petroleum

- ASTM A213/ ASME SA213 T9 for petroleum

- ASTM A213/ ASME SA213 T91 for power generation

- ASTM A213/ ASME SA213 T92 for power generation

- SA209 T1 for boiler replacement and repair

- ASTM A213/ ASME SA213 SA213 T11 tube for Manufacturing Boilers

- ASTM A213/ ASME SA213 SA213 T11 tube for Superheaters

- ASTM A213/ ASME SA213 SA213 T11 tube for Heat Exchangers

ASTM A213/ ASME SA213 T9 Alloy Steel Boiler and Heat Exchanger Tubes

| ASTM | ASME | JIS G 3462 | BS | DIN | ISO | ABS | NK | LRS | DNV |

|---|---|---|---|---|---|---|---|---|---|

| A209 T1 | SA209 T1 | STBA 12 | 3606 243 | 17175 15Mo3 | 2604 II TS26 | ABS K | KSTB 12 | Sec 4-E-TS380 | |

| A250 T1 | SA250 T1 | 3606 245 | 17177 15Mo3 | 2604 III TS26 | |||||

| A209 T1a | SA209 T1a | STBA 13 | ABS L | ||||||

| A250 T1a | SA250 T1a | ||||||||

| A213 T2 | SA213 T2 | STBA 20 | 17175 14MoV83 | 2604 II TS33 | Sec 4-E-TS440 | ||||

| A250 T2 | SA250 T2 | ||||||||

| A213 T12 | SA213 T12 | STBA 22 | 3606 620 | 17175 13CrMo44 | 2604 II TS32 | ABS O | KSTB 22 | Sec 6 1Cr 1/2Mo-440 | Sec 4-E-TS410-3 |

| A250 T12 | SA250 T12 | 2604 III TS32 | |||||||

| A213 T11 | SA199 T11 | STBA 23 | 3606 621 | ABS N | KSTB 23 | Sec 4-E-TS410-4 | |||

| SA213 T11 | |||||||||

| A213 T22 | SA199 T22 | STBA 24 | 3606 622 | 17175 10CrMo910 | 2604 II TS34 | ABS P | KSTB 24 | Sec 6 2-1/2Cr 1Mo-410 | Sec 4-E-TS450-2 |

| SA213 T22 | |||||||||

| A213 T5 | SA199 T5 | STBA 25 | 3606 625 | 2604 II S37 | Sec 4-E-TS430 | ||||

| SA213 T5 | |||||||||

| A213 T9 | SA199 T9 | STBA 26 | 3059-P2 622-490 | 2604 II S38 | Sec 4-E-TS500 | ||||

| SA213 T9 | |||||||||

| A209 T1b | SA209 T1b | 3059-P2 243 | 17175 17Mn4 | 2604 II S39 | ABS M | Sec 6 2-1/2Cr 1Mo-490 | Sec 4-E-TS450-1 | ||

| 3059-P2 620-460 | (=A209- T1b) | ||||||||

| A250 T1b | SA250 T1b | 3059-P2 629-470 | 17175 14MoV63 | 2604 II S40 | Sec 4-E-TS460-2 | ||||

| A250 T11 | SA250 T11 | 3059-P2 629-590 | 17175 X20CrMoV12 1 | Sec 4-E-TS590 | |||||

| A250 T22 | SA250 T22 | 3059-P2 762 | Sec 4-E-TS610 | ||||||

| A213 T5b | SA213 T5b | 3059-P2 304S51 | Sec 4-E-TS690 | ||||||

| A213 T5c | SA213 T5c | 3059-P2 306S51 | |||||||

| A213 T17 | SA213 T17 | 3059-P2 316S52 | |||||||

| A213 T21 | SA213 T21 | 3059-P2 316S51 | |||||||

| A213 T23 | SA213 T23 | 3059-P2 321S51 | |||||||

| A213 T91 | SA213 T91 | 3059-P2 347S51 | |||||||

| A213 T92 | SA213 T92 | 3059-P2 215S15 |

Diffrent Types of SA213 T9 Tube

| AISI SA213 t9 Alloy ERW Tube Stockist in India. | ASTM A213 T9 Tubes supplier in India. |

| SA213 T9 Alloy Steel Tubes Suppliers in India. | ASTM A213 T9 Alloy Steel A335 Tube supplier in India. |

| ASTM A213 t9 Tubes Stockist in India. | ASTM A213 T9 Alloy Steel Seamless Tube supplier in India. |

| SA213 T9 Alloy Steel Seamless Tubes Stockist in India. | Alloy Steel Gr SA213 T9 Heater Tube supplier in India. |

| SA213 T9 Alloy Steel Custom Tubes Stockist in India. | ASME SA / ASTM A213 T9 Tubes Manufacturer in India. |

| ASME SA213 T9 Alloy Steel Seamless Tube Stockist in India. | IBR SA213 T9 Alloy Steel Tubes Manufacturer in India. |

| Alloy A213 T9 Seamless Square Tube Stockist in India. | ASME SA213 T9 Alloy Steel Seamless Tube Manufacturer in India. |

Our All Product Facility

Api 5l Pipes & Tubes., ASTM A335 Alloy Pipes, Stainless Steel Pipes & Tubes., Stainless / Carbon Steel Plates and Sheets., Chrome Moly A213 Boiler Tubes, ASTM A213 T5 Chrome Moly Tubes, ASTM A213 T9 Chrome Moly Tubes, ASTM A213 T11 Chrome Moly Tubes, ASTM A213 T22 Chrome Moly Tubes, ASME SA387 Chrome Moly Steel Plate, Swaging Boiler Tube – Swaged Tube, Pipe Fittings., Stainless Steel Fittings, B16.9 Butt welded Fittings, ASME/ANSI B16.9 – Fittings, B16.9 Butt Welded Unequal tee, B16.9 Barred Tee / Bar Tee, Butt Welded Con. and Ecc. Reducer, Butt Welded Straight (Equal) Tee, Butt Welded End Cap, ASTM A234 Chrom-Moly Reducer, ASTM A234 Chrom-Moly Tee, B16.5 – Pipe Flanges & Flanged Fittings, EN 1092-1 Flanges , B16.9 High Nickel Alloy Fittings, B16.9 Hastelloy C276 Fittings, B16.9 Inconel 625 Fittings, Ferrule – Tube Inserts, Alloy 602CA – Ferrule (Tube Insert), Alloy 601 Ferrule (Tube Insert), High Temp. Tube Insert Sleeve, Metal Tube Inserts (Ferrules), Virgin PTFE Tube Inlet Ferrule, Sleeve ,Pipe Sleeving, Internally Insert Pipe Sleeve, Internally Pipe protaction Sleeve, Pipe Insert Sleeve, Repair Pipe Half Sleeve, Industrial Valve’s, Flanges, Gaskets & Flange Insulation Kit, Monolithic insulation joint – MIJ, Fasteners, Steel Equivalent

OUR MAIN STOCK AND EXPORT COUNTRIES:

- ASIA – India, Japan, Thailand, Singapore, Sri lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary,Belarus, Bulgaria, Slovakia, Moldova

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

- South America – Argentina, Chile, Brazil, Colombia, Paraguay

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger,Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara

- Southern Africa – South Africa, Namibia, Botswana,Lesotho, Swaziland

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda,Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles