Emergency Pipeline Repair Clamps Manufacturer

Aditya Steel Engineering Co. manufacture, fabricate and suppliers of split Sleeve Repair Clamps, Anti-Corrosion Products, Pipeline Custom Fittings, Pipeline Repair Clamps manufacturer, Pipeline Mechanical Couplings, Structural Pipe Repair Clamps, Split Sleeve Pipe Repair Clamps, Pipe Repair Split Sleeve, Stainless Steel Repair Clamp, Pipe Internal Insert Sleeves, Hot Tap Repair Fittings, Pipe Welding Alignment Clamp is the latest in the series of value-added, high performance, innovative products from Total Piping repair Solutions.

Aditya pipe repair clamp, pipe leak repair clamp, pipe clamp, emergency leak repair clamp, pipe leak stop clamp, heavy repair clamp, split Sleeve Repair Clamps, bolted repair split sleeve, Anti-Corrosion Products, Pipeline Custom Fittings, Pipeline Repair Clamps manufacturer, Pipeline Mechanical Couplings, Structural Pipe Repair Clamps, Split Sleeve Pipe Repair Clamps, Pipe Repair Split Sleeve, Stainless Steel Repair Clamp, Pipe Internal Insert Sleeves, Hot Tap Repair Fittings, Pipe Welding Alignment Clamp manufacturer and suppliers.

|  |  |  |

| Pipeline Mechanical Couplings | Structural Pipe Repair Clamps | Split Sleeve Pipe Repair Clamps | Pipe Repair Split Sleeve |

|  |  |  |

| Stainless Steel Repair Clamp | Pipe Internal Insert Sleeve | Hot Tap Repair Fittings | Pipe Welding Alignment Clamp |

MANUFACTURER AND FABRICATORS OF ALL TYPES OF EMERGENCY PIPE REPAIR PRODUCTS

Aditya Steel Manufacturers of split Sleeve Repair Clamps, Anti-Corrosion Products, Pipeline Custom Fittings, Pipeline Repair Clamps manufacturer, Pipeline Mechanical Couplings, Structural Pipe Repair Clamps, Split Sleeve Pipe Repair Clamps, Pipe Repair Split Sleeve, Stainless Steel Repair Clamp, Pipe Internal Insert Sleeves, Hot Tap Repair Fittings, Pipe Welding Alignment Clamp pipe repair clamp, pipe leak repair clamp, pipe clamp, emergency leak repair clamp, pipe leak stop clamp, heavy repair clamp, split Sleeve Repair Clamps, Anti-Corrosion Products, Pipeline Custom Fittings, Pipeline Repair Clamps manufacturer, Pipeline Mechanical Couplings, Structural Pipe Repair Clamps, Split Sleeve Pipe Repair Clamps, Pipe Repair Split Sleeve, Stainless Steel Repair Clamp, Pipe Internal Insert Sleeves, Hot Tap Repair Fittings, Pipe Welding Alignment Clamp manufacturer and suppliers.

PIPELINE REPAIR PRODUCTS :

Pipeline repair products are solutions used to repair and maintain pipelines, ensuring their integrity and functionality. Some common pipeline repair products include:

1. Pipe liners: These are used to line the inside of existing pipes, restoring their diameter and flow capacity.

2. Pipe wraps: These are used to reinforce and strengthen pipes, often used in conjunction with pipe liners.

3. Epoxy coatings: These are applied to the inside or outside of pipes to protect against corrosion and damage.

4. Polyurethane foams: These are used to fill gaps and holes in pipes, providing insulation and support.

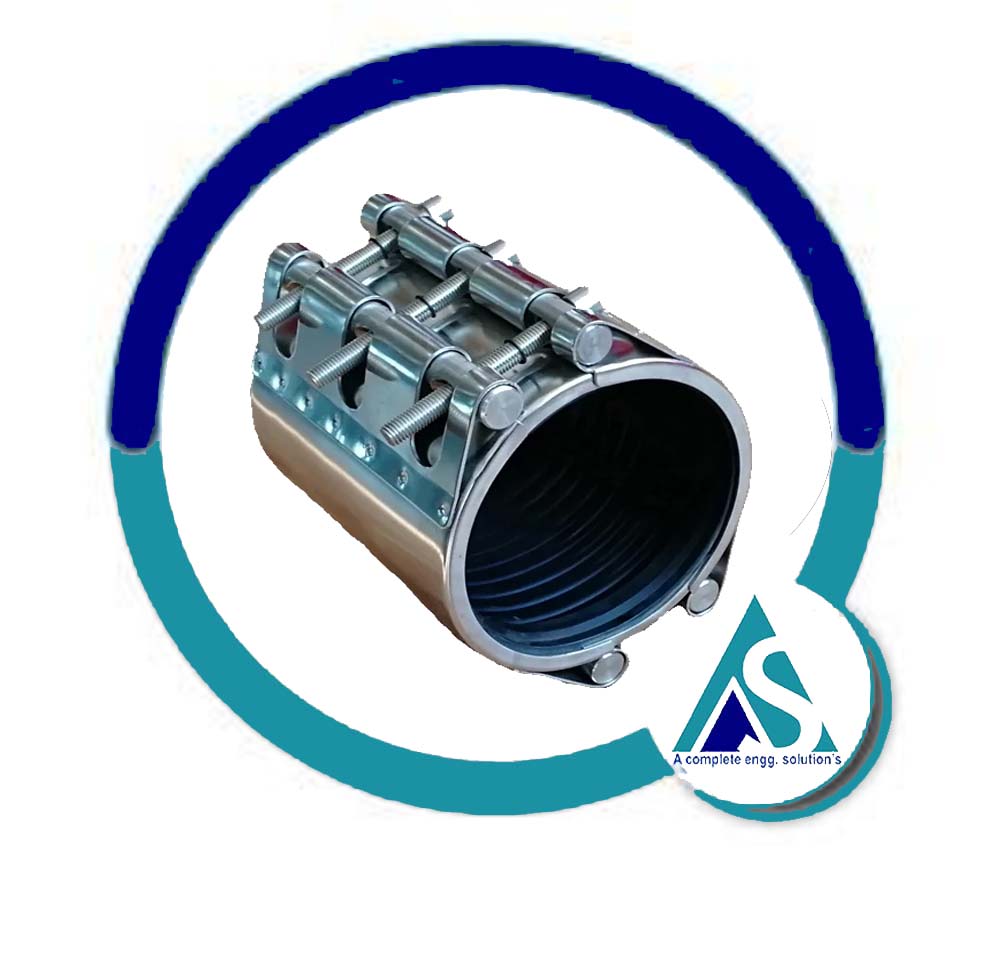

5. Clamps and couplings: These are used to connect and secure pipes, often in emergency repair situations.

6. Repair sleeves: These are used to cover and reinforce damaged sections of pipe.

7. Trenchless repair products: These are used for trenchless pipe repair, minimizing excavation and disruption.

Pipeline repair clamps are devices used to connect, repair, or reinforce pipelines. They are typically used to:

1. Repair cracks or leaks in pipelines

2. Connect new pipes to existing ones

3. Reinforce weakened areas of pipelines

4. Change pipeline direction or configuration

Types of pipeline repair clamps we produce:

1. Encapsulation clamps: Wrap around the pipe, encapsulating the damaged area

2. Mechanical clamps: Use bolts or screws to secure the clamp to the pipe

3. Hydraulic clamps: Use hydraulic pressure to secure the clamp to the pipe

4. T-Bolts clamps: Use T-shaped bolts to secure the clamp to the pipe

5. Hinged clamps: Allow for easy installation and removal

6. Flanged clamps: Connect to flanged pipes or fittings

7. Coupling clamps: Connect two pipes together

8. Line stop clamps: Allow for hot tapping and line stopping

Pipeline repair clamps are made from materials such as:

1. Carbon Steel:

– ASTM A105 (Grade 1, 2, 3)

– ASTM A216 (Grade WCB, WCC, LCB, LCC)

– ASTM A352 (Grade LCB, LCC)

– ASTM A516 GRADE 70

2. Stainless Steel:

– ASTM A182 (Grade F304, F316, F321, F347)

– ASTM A351 (Grade CF8, CF8M, CF3, CF3M)

3. Aluminum:

– ASTM B26 (Grade 6061-T6, 6063-T5, 356-T6)

– ASTM B85 (Grade 7075-T6, 2024-T4)

4. Ductile Iron:

– ASTM A536 (Grade 65-45-12, 80-55-06, 100-70-03)

5. Plastic (for non-metallic pipes):

– ASTM D1785 (Grade PVC 1120, 1220, 2120)

– ASTM F2165 (Grade PP 1000, 2000, 3000)

When selecting pipeline repair clamps, consider factors such as:

1. Pipe size and type

2. Pressure rating

3. Temperature range

4. Corrosion resistance

5. Ease of installation and removal

6. Cost and availability

PIPE REPAIR PRODUCTS MATERIAL SPECIFICATIONS :

- ANSI pressure classes 300, 400, 600, 900 and 1500

- Design based on: ASME Sec. VIII, API 6H , ANSI B31.4, B31.8 and Split Sleeve Software 3S)

- Design control and stress analysis with Finite Element Package

- Body materials: A216 WCB, A216 WCC, A352 LCC, A516 Gr.70 (Suitable for normally corrosive services)

- Stud material: A193 Gr. B7, Nut material: A 194 Gr. 2H

- Coating: Yellow Epoxy Polyamide, standard or Marine epoxy

- The highest quality NBR or VITON elastomer seal precisely compatible with the line fluid and ambient temperature will be installed into the split sleeves

- NBR temperature range is from – 20 C to + 80 ̊ C̊

HNBR temperature range is from – 20 C to + 150 ̊ C̊

VITON temperature range is from – 20 C to + 200 ̊ C - Gaskets are replaceable without any special tools.

- Girder rings can be installed upon cleints request.

- Double Row Sealing (DRS) design is also available.

This special design is more suitable for where probable leakage is much costly or dangerous; such as gaseous services & offshore applications.

Products for pipeline maintenance and repair from Emergency enabling quicker, safer, and simpler offshore repairs clamps and sleeves.

OUR PIPELINE REPAIR PRODUCTS MANUFACTURING, FABRICATION AND EXPORT COUNTRIES:

ASIA – India, China, Japan, Thailand, Singapore, Sri Lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Turkmenistan, China.

Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Azerbaijan, United Arab Emirates.

Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein

Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova.

Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands

Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See

South America – Argentina, Chile, Brazil, Colombia, Paraguay.

Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena

Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara.

Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland

Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles